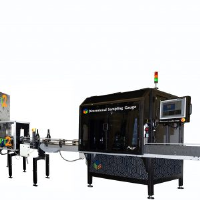

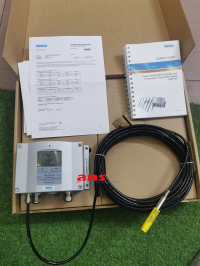

Dimensional Sampling Gauge 400 (DSG400), AGR Vietnam

Xuất sứ: MỸ

Nhà cung cấp: AGR VIETNAM

Hãng sản xuất: AGR VIETNAM

♦ Dương Huỳnh Thảo My ♦

Sales Engineer ANS Vietnam

PHONE “+84 938.140.396”

IE-mailI my.duong@ansgroup.asia

ISkypeI my.duong@ansgroup.asia

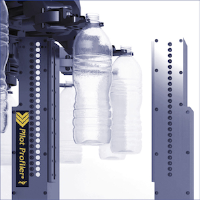

The Dimensional Sampling Gauge 400 (DSG400) is a high-precision automated measurement station for the glass container industry offering a multiplicity of new hardware, features and capabilities that further expand the handling, throughput, precision, communication and measurement functions of the DSG product line.

The DSG400 features state-of-the art optics, mechanical components and advanced measurement algorithms that makes it possible to perform even the most challenging measurements with high accuracy and repeatability.

The DSG400 meets the most stringent dimensional measurement requirements of bottle and container glass container manufacturing industry with a precision that is 10x greater than typical container design specifications. The DSG400 consolidates a number of critical measurements into one automated operation to facilitate maximum testing and measurement efficiency.

Features:

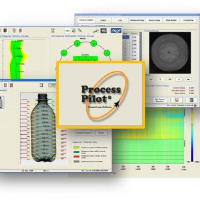

- Single user interface for all measurement operations

- Multiple measurement stations that operate simultaneously to maximize throughput

- Three-axis, pick and place robot to select containers and precisely place them in each station.

- Throughput of 100+ bottles per hour

- Advanced optical design with 360º imaging

- High image capture rate to define the smallest features with high repeatability

- Telecentric optics to ensure accurate measurements regardless of position

- Integrated thickness measurement (optional)

- Industry 4.0 standard communication

Multiple measurement functions in one operation

- Dimensional

- Bore

- Pushup

- Weight

- Sidewall thickness

Over 30 different measurements specifically for bottles and jars

- Multiple external body dimensions

- Height

- Comprehensive finish measurements

- Lean/Bent neck

- Tilt

- Angles and radii

- Summarizers for indirect measurement results

- Searchable “T” and “E”

- ID & Taper – depth to 90mm

- Locking angle

- Pushup/base clearance

- Weight

- Panel bulge and dip

- Knockout

- Flange

- Simple label panel scan

- Panel Area Scan for non-continuous labels

OTHER CONFIGURATIONS

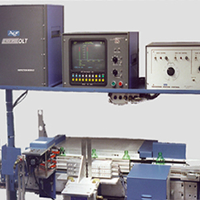

The DSG400 is also available in versions for small bottle/pharmaceuticals, multiple line configurations and as part of Agr’s OmniLab® system, which provides dimensional, thickness, volume and pressure measurement in one complete system.