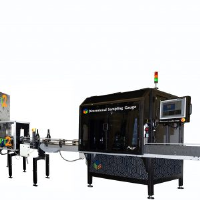

Pilot Profiler® Conveyor, AGR VIETNAM

Xuất sứ: MỸ

Nhà cung cấp: AGR VIETNAM

Hãng sản xuất: AGR VIETNAM

♦ Dương Huỳnh Thảo My ♦

Sales Engineer ANS Vietnam

PHONE “+84 938.140.396”

IE-mailI my.duong@ansgroup.asia

ISkypeI my.duong@ansgroup.asia

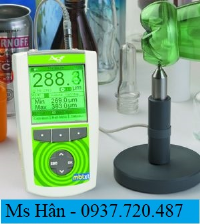

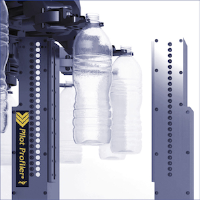

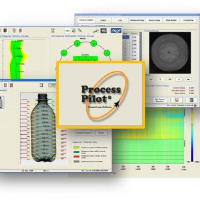

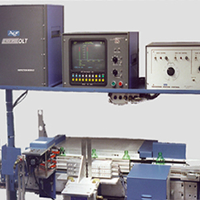

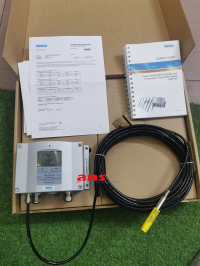

The Pilot Profiler® Conveyor system offers material distribution measurement of PET containers transported on a flat-bed conveyor. This system provides real-time data on material distribution and offers in-line process monitoring with laboratory accuracy, providing essential information for light weight operations, quality management and process control functions.

The Pilot Profiler Conveyor system features a conveyor mounted measuring station that can be fitted with up to 32 sensors. Bottles are measured as they pass by the station, providing a comprehensive thickness profile over the entire sidewall of every container.

Pilot products offer the following benefits

- Ability to monitor material distribution changes anywhere on the bottle

- Improved blowmolder management and monitoring capabilities

- Reduced job start-up time

- Elimination of destructive testing

- Ability to proactively manage lightweight activities

- Reduced held product, scrap and regrind

Features

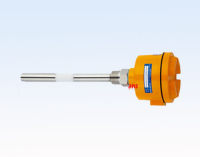

- Conveyor based mounting of sensors

- Up to 32 measurement locations

- On-going process reports identifying status and trends

- Multi-level control limits

- Built-in reject system for non-conforming containers

- Easy-to-understand user interface

- Throughput of up to 60,000 bph

- 100% production monitored